BETTER THROUGH INNOVATION

Sno-Way® has always been known as an innovator. You can just look at our beginnings when we started in 1978 building plows for 4 wheel drive cars. We developed the first see-through polycarbonate plow and then put the hydraulics out on the plow with electric operated valves and coils, eliminating levers and cables to operate the plow. Sno-Way® then became the first to allow you to remove the plow from the truck so the truck had the original factory look. Fast forward a few years, Sno-Way® introduced reactive Down Pressure® to the market. The innovation allows you with a touch of a button to put additional hydraulic force on the cutting edge. Just engage the system and it monitors itself, maintaining the scraping pressure on the cutting edge until you decide to turn it off. This system allows you to scrape surfaces cleaner, move more snow, and reduce the time spent plowing by about 30 percent.

Recent Innovations

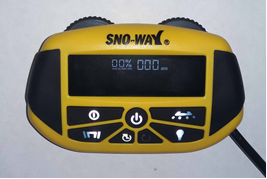

More innovation followed when we introduced wired and wireless microprocessor-based cab controls allowing you to have a single control operate every style of plow that Sno-Way® produces. You get complete flexibility to move plows from truck to truck during a storm without any wasted time. We also included programs in the control allowing you to train your plow to do multiple functions with one push of a single button, like moving a raised plow down and right all at once with a one-and-done click of a single button saving you time and keeping your focus on the snow and not the control.

The same control you use to control the plow will also control the Tailgate spreader on the back of the truck bringing you down to only one control for all your work and reducing the amount of wire that is brought into the cab compartment. Decluttering your cab and keeping one control hand saves you a lot of headaches over operating two separate controls.

Better Lighting Systems

Another innovation that Sno-Way® introduced is the EIS® Light System to control the plow and truck lights. Other systems depend on relays to control the truck and plow lights. The problem with mechanical relays is that they are a pain to install and they wear out and corrode if not properly maintained. When the relays fail you either lose your truck lights, plow lights or both, and by the way…it is expensive to replace relays. None of these scenarios work for you because if you need the lights and have none, you are shut down and done working. The EIS® Light System that Sno-Way® designed does not require any mechanical relays and this eliminates the entire bad situation that I just described because the relays can’t wear out or corrode because there are none in this system.

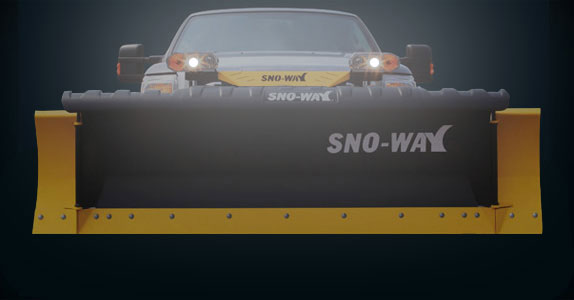

29 SERIES WITH 4-SIGHTTM (mouse over image to see 4 Sight activation)

Another system Sno-Way® developed that works with the EIS® Light System is a system we named 4-Sight™. This system is a harness that is added to the plow and taps into the EIS® Light System that will turn on the truck lights every time the plow is in the down position. When you put the plow down, the plow lights and the truck lights are on at the same time! This gives you double the lights that you would normally have. Who does not want more light when it is 2 A.M. in the morning? You need to see where you are plowing, your eyes are tired from being up for 36 hours, more light makes the job a whole lot easier. The best thing is anytime you touch the up button on the control to raise the plow, the truck lights go out automatically, so you do not have the truck lights reflecting off the back of the plow.

Innovation in Spreaders Too!

I have spent a lot of time explaining about plow innovation but I would be remiss if I did not talk about our latest innovation, our Revolution™ V-Box Spreaders. We designed a dual control auger drive system that will dispense any materials you need to spread to melt ice. This spreader does it all with our combination of an inverted vee system and our RS Control that makes this system truly revolutionary. The inverted vee gives you the flexibility to adjust the system to match the material that you need to spread. Our inverted vee system can be raised, lowered, have sections opened up, or completely remove sections to maximize the amount of material that will flow.

When you combine the inverted vee system with the RS Control, you have a match made in heaven (or at Sno-Way® in this case). The control monitors the auger system to maintain the speed of the auger and the amount of power needed to maintain the auger speed. With other controls, you need to reduce the voltage to the electric motor in order to decrease the speed of the auger.

The problem with the voltage is that it also reduces the torque the motor has to turn the auger. The resulting loss of torque means the auger cannot handle the loads of the material and just stops moving the auger, stopping the material flow at low flow, which means you have to shovel out the material from the spreader to reduce the load on the auger…not a good situation for you.

The RS Control is Your “Cruise Control”

The RS Control works like the cruise control on your truck, if you are going up a hill and you need more power, the truck automatically down shifts and increases the throttle, when you get to the top of the hill it up shifts and reduces the throttle so you maintain your speed. The RS Control basically does the same thing, when you have the control set to half speed, the control will monitor the auger and as the load changes on the auger it will increase or decrease the power to maintain the speed of the auger you have set.

The control also monitors the vibrator or vibrators in the system. When you put the system in auto mode, it will automatically turn the vibrator or vibrators on and off as needed. We developed this feature because the vibrator can help you or hurt you if left on too long or not long enough. If left on too long, the vibrator can pack the material so tight that the material stops flowing into the auger creating an empty cavity just above the auger, which means the spreader stops spreading.

If the vibrator or vibrators are not left on long enough, the material does not break up so you lack enough flow of material to the auger and you end up with the same problem, material not getting to the auger, which means the spreader stops spreading. With the system in auto mode, the vibrator or vibrators operate on their own and your driver concentrates on driving the truck, not on operating the vibrator system.

Auto Mode for the Wetting System!

With auto mode we can also operate the wetting system. This system is really slick because when you increase or decrease the auger speed, the wetting system output increases or decreases automatically to maintain the salt wetting ratio of the material. This way you are not over wetting and wasting material or under wetting and not achieving your desired results. This control has even many more features built into it and you can get more information from our website where we show you the RVB Spreaders and the RS Control.

Thank you so much for taking the time to read this. I hope you found it informative and understand that we will continue to be THE market leader in innovation. For more information on all of our products see our website www. snoway.com or better yet contact one of our dealers.